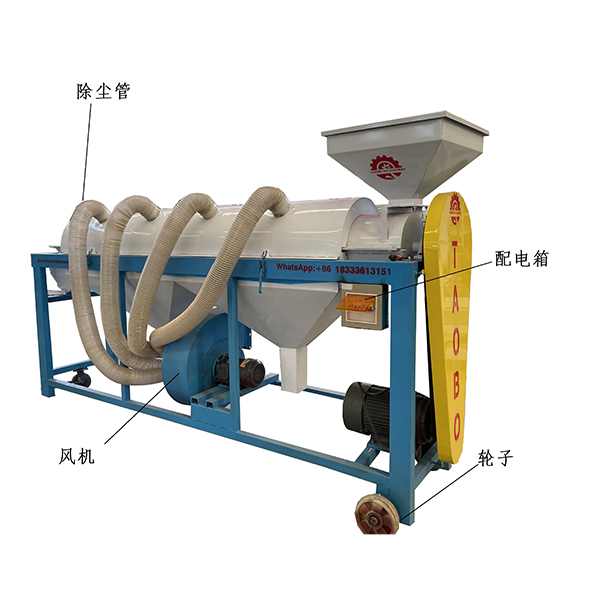

Naoa e khubelu, linaoa tsa mung, mochini o bentšang oa soybean bakeng sa ho hloekisa sefahleho se seretse / mochini o bentšang lijo-thollo tsa linaoa ke mofuta o mocha oa lisebelisoa tse bonolo tsa ho hloekisa le ho lokisa lijo-thollo. Lisebelisoa li kopanya mesebetsi e fapaneng e kang ho tlosa lijo-thollo, ho bentša lijo-thollo, le ho tlosa hlobo ea lijo-thollo. Ka mor'a ts'ebetso ea tlhahlobo e pheta-phetoang, thepa e finyelletse litšobotsi tsa matla a fokolang, boholo ba tlhahiso e kholo, ts'ebetso e bonolo, ha ho na lerōle sebakeng sa mosebetsi, ho bonolo ho tsamaea, le phello e ntle ea polishing, 'me e amoheloa hantle ke basebelisi ba ho lokisa lijo-thollo.

Mochini oa ho bentša lijo-thollo o sebelisoa haholo indastering ea ho lokisa lijo-thollo, haholo-holo bakeng sa ho deawning le ho bentša likaroloana tsa lijo-thollo tse kang linaoa, koro, raese, raese, lijo-thollo le liindasteri tse ling tsa ho lokisa peo, temo le lihlahisoa tsa lihlahisoa tse ka thōko, joalo-joalo, haholo-holo bakeng sa linaoa tse seng li hloekisitsoe. Mabele a sebetsa hantle. Lihlahisoa tse entsoeng ke thepa ena li khanya ebile li hlakile, li na le qetello e ntle, 'me boleng ba thepa bo ntlafatsoa le ho feta.

1. Mohlala ona o nka mochine oa vibration e le mohloli oa ho sisinyeha, sebaka se hlokahalang sa amplitude le vibration direction angle se ka fetoloa habonolo le ka nepo, 'me ha se tšabe pula; e hanyetsana le mocheso o phahameng le mocheso o tlase, 'me e na le ts'epo e matla.

2. Mochine oa hoist o kopane, o feto-fetoha le maemo, o bonolo ho o hlokomela, 'me o ka ts'oaroa le ho sisinyeha ho ikamahanya hantle le maemo a fapaneng a ho sebetsa.

3. Elevator e nang le li-silinda tse peli e ka thibela ka katleho hore lijo-thollo tse oelang li se ke tsa kena lebiling le khannoang, kahoo li fokotsa haholo extrusion le ho senya.

4. Li-elbows tsohle li sebelisa theknoloji ea ho loma ka mechine ho felisa mefokolo ea li-welding, ka ho tiisa hantle, ho hanyetsa le ho tšoarella;

5. Sebopeho se utloahalang sa ho tlosa lerōle la leholiotsoana, le ho kenngoa ha valve e thata ea ho ntša lerōle la rotary ho fokotsa ho tsoa ha moea, ho ntlafatsa katleho ea ho tlosa lerōle, le ho etsa hore sebaka sa ho sebetsa se hloeke le ho boloka tikoloho.

6. bolo e khethiloeng ea ho hloekisa rabara e na le litšobotsi tsa elasticity e phahameng, ho hanyetsa serame le ho hanyetsa botsofali. E ntse e ka hloekisoa ka katleho mariha le ho ntlafatsa ho phunyeletsa ha skrine.

7.E na le mefuta e mengata ea lits'ebetso mme e ka sebelisoa indastering ea ho lokisa peo le liindasteri tsa temo le tse ka thoko. E na le phello e ntle ea ho hloekisa peo ea lijo-thollo, peo ea lifate tsa meru, peō ea furu, peo ea oli, lijo-thollo tse fapa-fapaneng le lijo-thollo tsa khoebo, joalo-joalo. Ho sebetsa ka ntle ho naha ea lihlahisoa tsa temo le tse ka thōko (tse kang linaoa tse khubelu tsa Adzuki, linaoa tsa soya, linaoa tsa mung, peo ea soneblomo, peo ea mahapu, joalo-joalo) le tsona li ka sebelisoa.

Morero o ka sehloohong oa mochini oa polishing:

1: Sesebelisoa sa ho awning pele ho sebetsa peo,

2: Tlosa lerōle holim'a lijo-thollo tse feletseng

3: Eketsa bokaholimo le khanya ea lijo-thollo tse felletseng

4: Tlosa hlobo holim'a lijo-thollo

Nako ea poso: Oct-26-2022